- [新闻]-->INNOVA花式纱线纺纱机-功能强大的纱线创新设备

- [新闻]-->B5和B6立锭走架纺纱机改造为B7控制系统

- [新闻]-->高效节能的OPTIMA-e型雪尼尔纺纱机特点

- [产品]-->BIGAGLI自动立锭走架细纱机Proxima B7 DD

- [产品]-->意大利ABA公司新型MB13粗纺梳毛机简介

- [产品]-->INNOVA花式纱线纺纱机

产品推荐

产品分类

联系方式

- 联系人:张希红

- 邮 箱:bjzf@cta.com.cn

- 地 址:北京市朝阳区延静里中街3号

- 手 机:13611263985

- 电 话:010-65003727

- 传 真:010-65002491

- 网 址:http://www.cta.com.cn

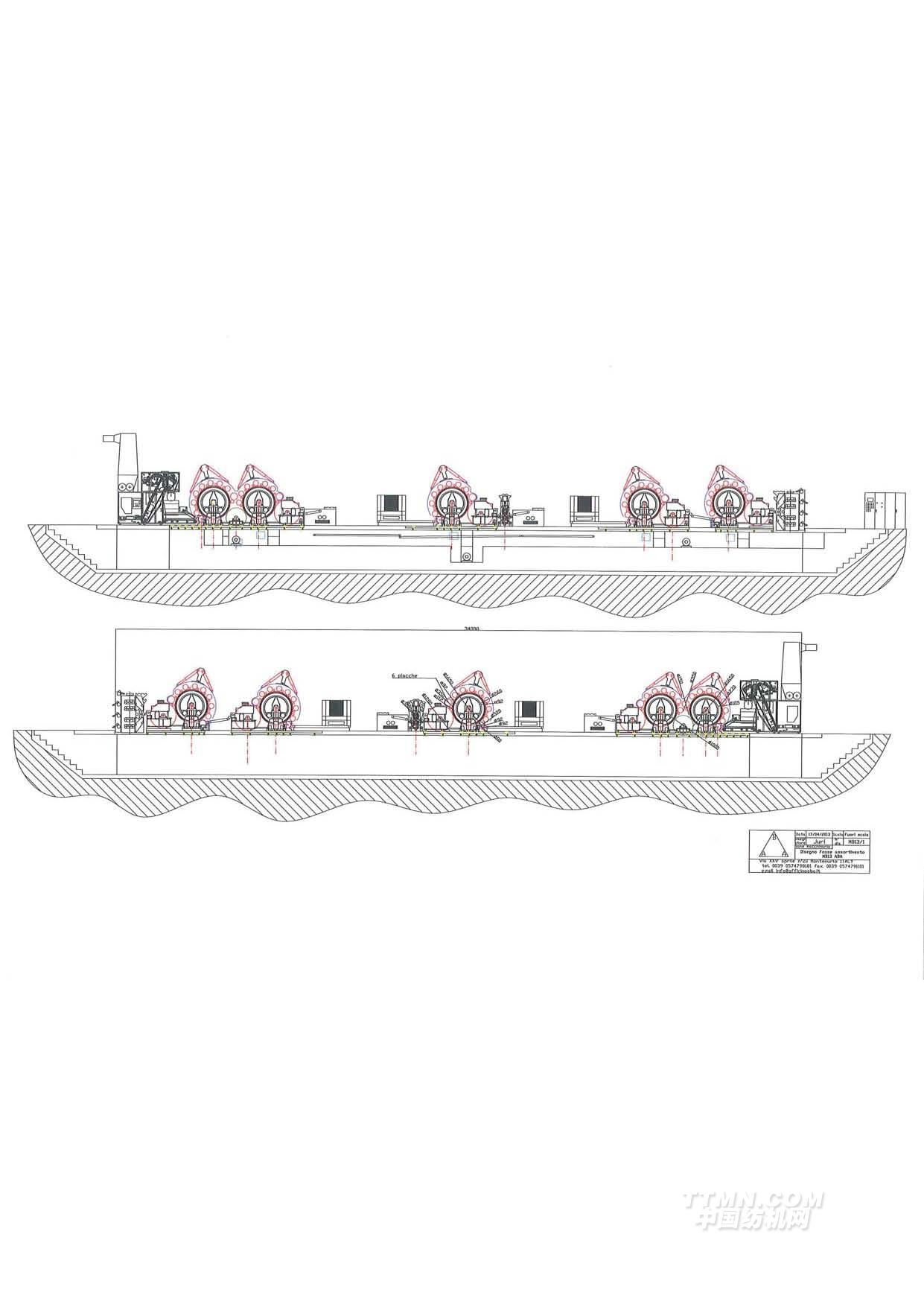

意大利ABA公司新型MB13粗纺梳毛机简介

发布时间:2013-06-03

NEW CARDING SET siutable for high quality cashmere, working with: 1800mm, 2000mm or 2500mm, all in single block steel composed as follows:

全新梳毛机,适合生产高质量粗纺羊绒纱,幅宽: 1800mm, 2000mm 或2500mm,所有主结构为整体钢制结构,组成如下:

- N.1 AUTOMATIC HOPPER FEEDER

N.1 自动喂毛斗

- N.1 BREAST

N.1胸锡林

- N.1 FIRST CARD

N.1第一梳理组

- N.1 FIBER TRANSPORTER OF 45° WITH UNDERGROUND PASSAGE

N.1下过桥

- N.1 INLET BENCH

N.1喂入帘

- N.1 SECOND CARD

N.1第二梳理组

- N.1 PERALTA

N.1压草辊

- N.1 FIBER TRANSPORTER OF 45° WITH UNDERGROUND PASSAGE

N.1下过桥

- N.1 INLET BENCH

N.1喂入帘

- N.1 THIRD CARD

N.1第三梳理组

- N.1 CONVEYOR BELT FOR VEIL to the fourth finishing card

到第四梳理组的毛网输送帘

- N.1 FOURTH CARD (FINISHING CARD)

N.1第四梳理组(末梳)

- N.1 DIVIDING CONDENSER WITH SINGLE BELT

N.1单根分割车头

- N.1 FLOATING BENCH

N.1搓皮板车架

- N.1 SUPERCHAMMLER FOR MATERIAL RECOVERY

N.1往复卷绕车架

AUTOMATIC HOPPER FEEDER composed as follows:

自动喂毛斗组成如下

- Steel carrying flanks

钢制机架

- N.1 scale with pneumatic opening, electronic loading bins

1台称量装置带气动开斗,电子装料箱

- N.1 counter-scale with pneumatic functioning for stopping the eventual falling material once the weighing is carried out

一旦称重完成数字称带气动功能控制浮游纤维

- N.1 electronic terminal composed by one multiprocessor system for the weight management

电子终端由多处理系统组成用于管理称重

- N.4 motoreducers for conveyor belts control, everything controlled by general electric control panel by means of n.4 inverters

4个减速电机用传送帘子控制,所有过程由4个变频器驱动

- N.1 switchboard equipped with PLC for the management of the various working phases of the machine

配电盘装备PLC控制管理各工作周期

- Everything completed with conveyor belts in PVC fitted on polyzene guides

包括PVC传送帘的所有部件都装在Polyzene导辊上

- Dragging of the main conveyor belt by means of rolls Ø 200mm

直径193毫米辊传动主帘

- N.1 feeding bench to the breast cylinder with inclined belt for conveying material to inlet cylinders

胸锡林喂入帘上有斜压帘

- Machine completely fitted on bearings

全轴承化

BREAST equipped with inlet group composed by

胸锡林带喂入组件组成如下:

- Structure in steel with outside foot support

钢构件带外支撑脚

- N.2 inlet cylinders Ø 92 mm with rigid clothing and N. 1 Discharge Cylinder Ø 80

2个直径92毫米喂入辊,包金属针布,1个直径80毫米剥取辊

- N.1 inlet cylinder Ø 320 mm with rigid clothing

1个直径320毫米开毛辊,金属针布

- N.1 Breast drum Ø 1650 mm

1个胸锡林直径1650毫米

- N.7 couples of workers Ø 270mm and Striper Cylinder Ø 105mm

7对直径270毫米工作辊和直径105毫米剥毛辊

- N.1 couple of worker Ø 350mm and Striper Cylinder Ø 150mm

1对直径350毫米工作辊和直径150毫米剥毛辊

- Pneumatic Cup rising system on upper cover of Card

胸锡林上罩气动提升系统

- N.1 Transfer Cylinder for material to First Card ø 1000mm

1个转移辊直径约1000毫米

CARDS composed by

各道梳理机组成:

- Structure out of steel with outside foot support

钢构件带外支撑脚

- N.1 Card drum Ø 1650 mm

锡林直径1650毫米

- N.7 couples of workers Ø 260mm and Striper Cylinder Ø 92mm

7对直径260毫米工作辊和直径92毫米剥毛辊

- N.1 fly-wheel Ø 350 mm

风轮直径350毫米

- N.1 lower Fly wheel Ø 112 mm

下挡风直径112毫米

- Pneumatic Cup rising system on upper part of Card

锡林上罩气动提升系统

- N.1 Doffer Ø 1280 mm

道夫直径1280毫米

- Doffing comb

斩刀箱

CONDENSER WITH single belt

单根分割车头:

- Frame out of steel

钢制墙板

- Machine completely fitted on bearings

全部装备滚柱轴承

- N. 2 web tensioning cylinders ø 120 mm out of anodized aluminum

2根毛网张力辊直径120毫米,阳极电镀铝制

- N. 2 Grooved splitting cylinders ø 120 mm with steel-ringed aluminum parts

2根有槽分割辊直径120毫米,钢环铝部件

- N. 2 grooved preparatory guide cylinders Ø 104mm

2根有槽导向辊直径104毫米

- N. 6 Steel preparatory-holders cylinders Ø 92mm

6根预握持辊

- Variator for web tensioning between rubbing aprons and preparatory

在搓皮板和预固定辊之间毛网张力变速器

FLOATING BENCH composed by

搓皮板架组成如下:

- Carrying structure in steel

钢制支撑构件

- Tempered and rectified shafts to cylinders floating bench sliding on self-lubricating bushings

回火调校轴到搓皮板架辊滑动在自润滑轴承中

- Machine completely assembled on ball bearings

机器完全安装在滚珠轴承上

- Big floating bench with blank from sleeves 1080 mm

大搓皮板框架可容纳外周长1080毫米的搓皮板

- N.12 support cylinder for rubbing aprons

12根搓皮板支撑轴

- Shaft column ø 50mm with eccentrics on clamping

立轴直径50毫米带偏心筘位

- Equalizer in monoblock steel with central temperate pins on roller bearings

整块钢制均衡器带中心销,装有滚柱轴承

- Bearings with double series on each head of cylinders for moving rubbing aprons

移动搓皮板的轴头装有双列轴承

GENERAL TECHNICAL FEATURES OF THE MACHINE

机器总的技术特点:

- Variator for the right veil tightening present in all passage phases from one working cycle to the following one

所有梳理组的工作周期由变速器调整正确的毛网张力

- Speed Variator for the control of one cam column of the floating benches

变速器控制搓皮板的凸轮立轴

- Speed Variator for material outlets of cards

变速器控制梳理机的毛网输出

- Speed Variator for doffing combs

斩刀变速器

N.1 COMPLETE LATERAL PROTECTION GUARD on wheels with transparent polycarbonate

整套带轮子聚碳酸酯透明窗侧防护装置

N.1 ELECTRIC CONTROL PANEL for Carding Set with following features:

控制整台机器的电控柜具有以下特点:

- Management of N.3 AC motors driven by inverters

由变频器控制管理3台交流电机

- False threads suction control

边条回收吸风控制

- Line for Hopper Feeder feeding

毛斗喂入在线控制

- Control of all various work steps of the machine and security by means of PLC and operator interface panel

由PLC和操作交互界面控制柜控制机器的各个工作步骤和安全

- Machine diagnostics

机器诊断

- Ventilation for cooling

通风装置用于冷却