- [新闻]-->INNOVA花式纱线纺纱机-功能强大的纱线创新设备

- [新闻]-->B5和B6立锭走架纺纱机改造为B7控制系统

- [新闻]-->高效节能的OPTIMA-e型雪尼尔纺纱机特点

- [产品]-->BIGAGLI自动立锭走架细纱机Proxima B7 DD

- [产品]-->意大利ABA公司新型MB13粗纺梳毛机简介

- [产品]-->INNOVA花式纱线纺纱机

产品推荐

产品分类

联系方式

- 联系人:张希红

- 邮 箱:bjzf@cta.com.cn

- 地 址:北京市朝阳区延静里中街3号

- 手 机:13611263985

- 电 话:010-65003727

- 传 真:010-65002491

- 网 址:http://www.cta.com.cn

RECOLINE废旧纺织品回用生产线

发布时间:2017-01-04

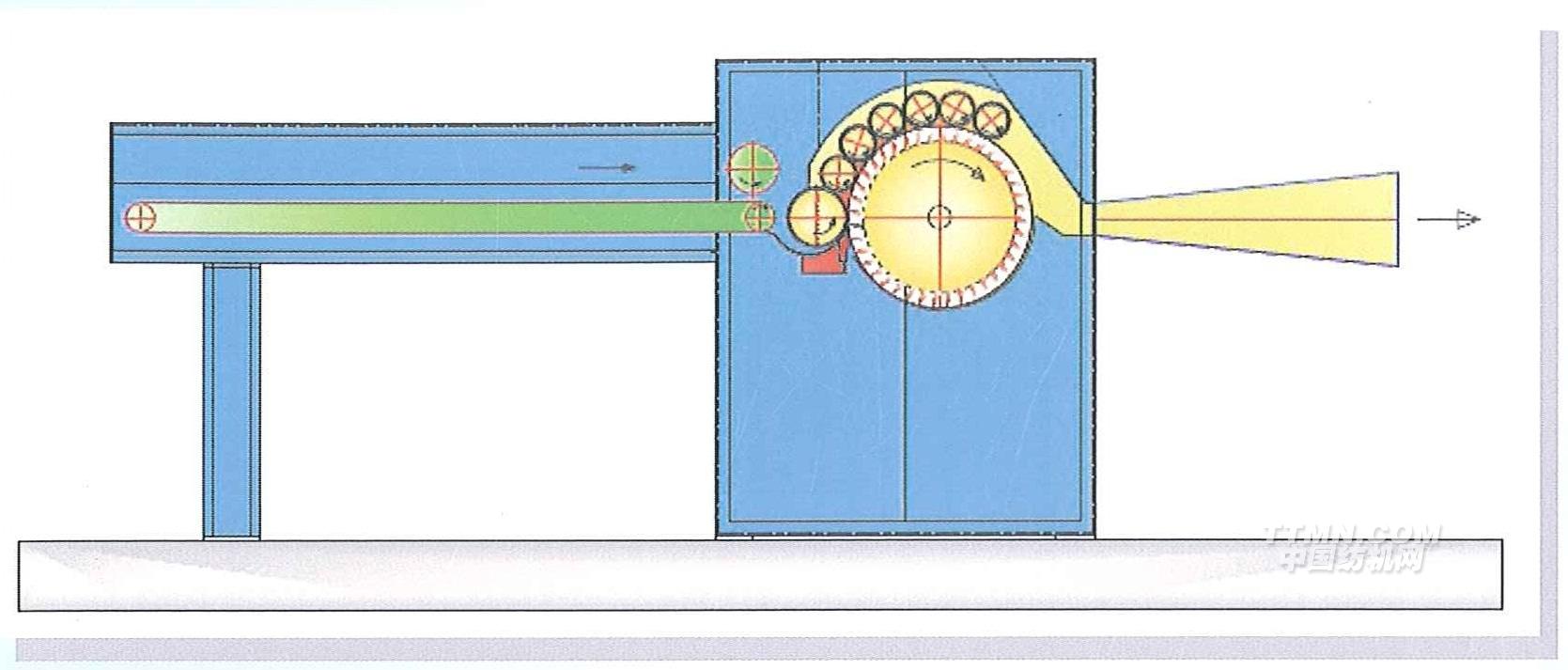

RECOLINE Textile waste reclaiming machines and plants with OpenMax – APM

RECOLINE 配置OpenMax – APM多功能多用途神奇开松机的废旧纺织品

回用生产线

HARD TEARING POWER● SOFT ON FIBER● LOW ON ENERGY CONSUPTION

强力撕裂●柔和开松●耗能低

RECYCLING 废旧纺织品回用生产线

Rotary Cutters 切割机

Pre-Openers 预开松机

Automatic Blenders and Feeders 自动混合和喂入设备

Impurities and Dust Separators 杂质和灰尘分离装置

Tearing lines composed from 2 to 6 opening sections 撕裂/开松加工: 2-6个开松单元

RECOLINE is composed by one or more in-line groups of OpenMax-APM, a very robust a versatile machine with the Ommi’s new system that is providing unique of his kind result in this field, indeed with the least energy consumption and the most in quality of opening and integrity of fibbers.

RECOLINE废旧纺织品回用生产线中有一个或多个OpenMax – APM多功能多用途神奇开松单元。OpenMax配置奥米公司新的专利系统,是这个领域的独创, 最大限度节能,彻底开松纤维并最大限度保护纤维。

A condenser unit assures the passage of material from one group to the next. The new exclusive design of the condenser unit and its motorized lateral movement together with the automatic lifting of the lids and the consequent release of the side protections allows a quick reach for cleaning and maintenance of one condenser and two opening groups. The first group is always equipped with the unopened bits recovery unit (fed back into the system) with flap opening adjustment by a linear actuator while the machine is running.

纤维凝聚器确保纤维从一个开松单元输送到下一个开松单元。纤维凝聚器设计独特、电动横向运动、盖子自动提升后两侧防护装置打开,以上使得纤维凝聚器和两组松单元易于清洁和维修。第一个开松单元配置有未开松碎片回收装置(回喂到系统中),设备运转时驱动器调整折翼开合将未开松碎片回喂到系统中。

RECOLINE is a multi material reclaiming line and system that works with technological concept. It is designed for regenerating any type of textile waste coming from spinning, weaving, knitting, nonwoven, garments … with a very powerful tearing action and at the same time with gentle effect on the fibers to make possible a re-use in the original process.

RECOLINE是适合多种废旧纺织品的高技术含量回用生产线和系统,适用于各种废旧纺织品的回用,包括回丝、废旧机织物、废旧针织物、废旧非织造布,废旧服装等等…

RECOLINE will soon becomes synonymous of optimal quality of the processed material, versatility and easiness of operation, high output, minimum maintenance, maximum saving of energy consumption.

RECOLINE意味着质量高、用途多、操作容易、产量高、维修量少、节能。

OpenMax is a robust and versatile machine to be used successfully either for a delicate but deep opening of fibers in the best conditions for the subsequent process or for the recycling of various types of waste materials coming from textile activities such as spinning, weaving, knitting, nonwoven etc…

多功能多用途神奇开松机OpenMax功能强大、适用范围广,以最好的方式柔和且充分开松纤维,可用于纤维的混合,也可用于纺织行业各领域废旧纺织品的回用,如回丝、 废旧机织物、废旧针织物、废旧非织造布,等等… 。

OpenMax works with a new system patented by Ommi, that assure a very high power of tearing and/or opening but with a delicate effect on the fibers. This is possible because the actual tearing /opening is applied in the same direction of the material movement and with an action on the fibers similar to the one of carding. High output, optimal quality of the processed material, versatility of use with adjustments possibilities, very low consumption of energy makes this machine a real innovation in the field!

多功能多用途神奇开松机OpenMax配置奥米公司新的专利系统,保证充分撕裂/开松,但对纤维的损伤很小。此专利系统在原料的运行方向实施撕裂/开松,类似于梳理工序。

OpenMax多功能多用途神奇开松机因产量高、成品质量好、用途广、耗能低成为这领域的独创!

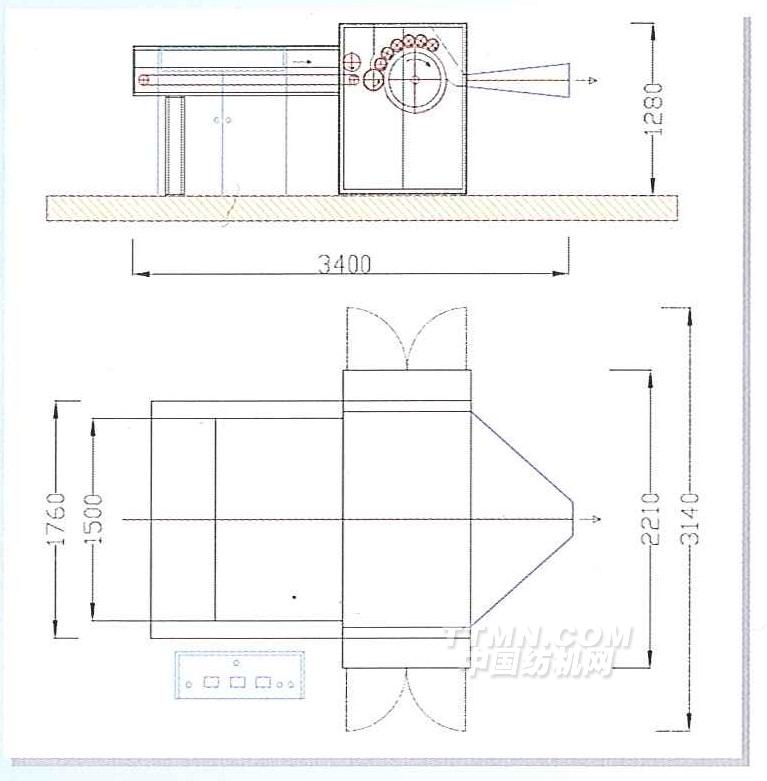

TECHNICAL CHARACTERISICS “APM-7” 技术参数

Worrking Width: 1000-1500mm

工作宽度: 1000-1500mm

Main Drum: dia.520mm

大滚筒直径: 520mm

Main Drum Clothing: pins or rigid

大滚筒针布: 角钉或金属针布

Main Drum Drive: variable speed with inverter

大滚筒传动 : 变频调速

Feeding Group: PVC belt with pressing cylinder

喂入装置: PVC传送带+压辊

Introduction Group: clothed cylinder and cradle

输入单元: 配置针布的锡林和托盘

Feeding-Introduction Drive: variable speed with inverter

喂入-输入单元传动: 变频调速

Workers Roller: 1+6 with rigid clothing

工作辊: 1+6 配置金属针布

Workers Drive: variable speed with inverter

工作辊传动: 变频调速

Machine Control Panel: centralized with touch screen mounted on the electrical cabinet

设备控制面板: 位于控制柜,配置触摸屏

Installed Power: 15-20Kw

安装功率: 15-20Kw

Minimum Air Pressure: 7-8 Bar

最低空气压力: 7-8 Bar

Metal Detector: with electric circuit on the introduction isolated cylinder

金属探测器: 安装在独立的输出锡林上

Anti-full Control: with pressure switch placed on the exit chute

防过满控制: 位于输出槽,配置压力开关

Material Feeding: manual or with automatic feeding units

原料喂入: 人工或配置自动喂入单元

Impurity or Patch Discard: with adjustable interceptor and recuperating vacuum system

杂质去除: 配置有可调的拦截器和真空系统

Accessibility: with hinged covers safety interlocked

辅助装置: 安全连锁的铰链防护罩

Productivity: Productivity: Highly productive with best possible quality levels

产量: 高质高产

For Recycling:

适用范围:

-Non woven such as edge trims or pieces of spun lace – needle punched – thermo bico

无纺布,包括水刺、针刺、热熔的下脚料

-Fabric such as jeans – cotton knits – polyester fabrics

织物,例如牛仔布、棉针织布、涤纶布

- Sweaters and fabrics of cashmere, wool, acrylic

羊绒、羊毛、腈纶等的毛衫和布

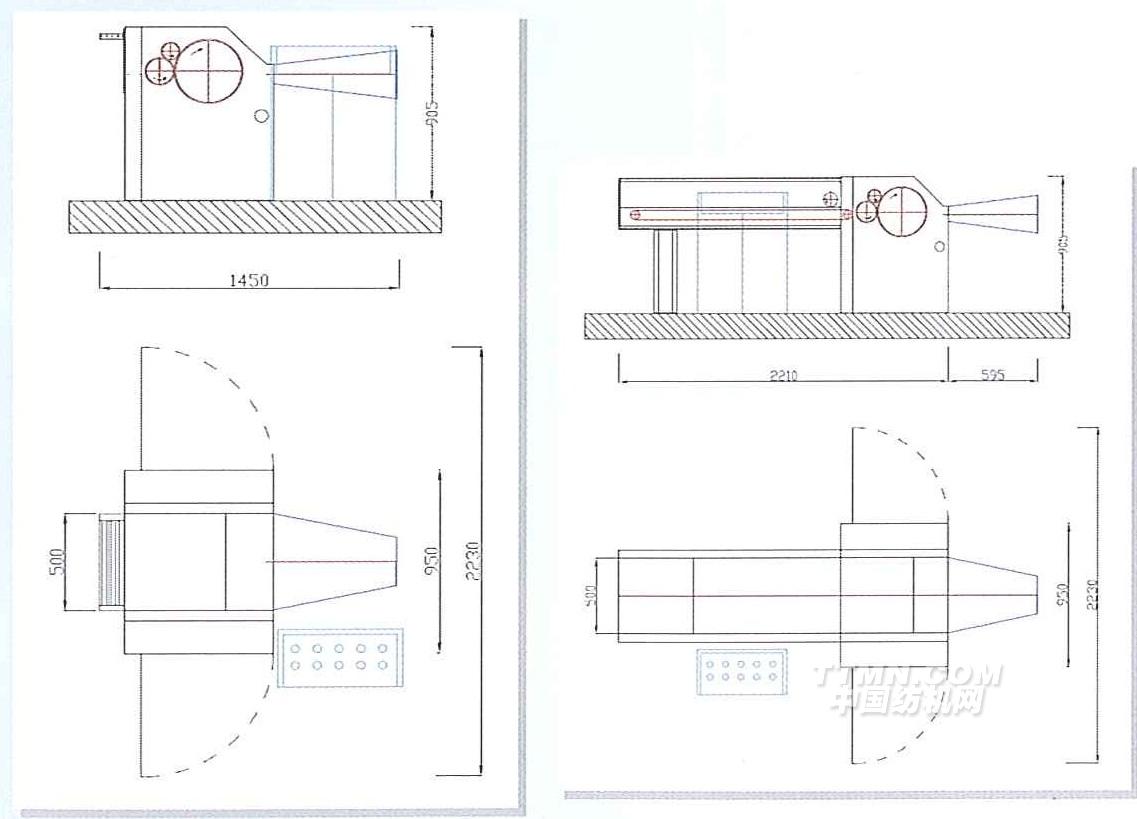

TECHNICAL CHARACTERISICS “APM-2” 技术参数

Worrking Width: 500-800mm

工作宽度: 500-800mm

Main Drum: dia.350mm

大滚筒直径: 350mm

Main Drum Clothing: pins or rigid

大滚筒针布: 角钉或金属针布

Main Drum Drive: variable speed with inverter

大滚筒传动 : 变频调速

Feeding Group: PVC belt with pressing cylinder or direct for selvedges

喂入装置: PVC传送带+压辊 或布边直接喂入

Introduction Group: clothed cylinder and cradle

输入单元: 配置针布的锡林和托盘

Feeding-Introduction Drive: variable speed with inverter

喂入-输入单元传动: 变频调速

Workers Roller: 1+1 with rigid clothing

工作辊: 1+1 配置金属针布

Workers Drive: variable speed with inverter

工作辊传动: 变频调速

Machine Control Panel: centralized with controls on the electrical cabinet

设备控制面板: 位于控制柜

Installed Power: 8Kw

安装功率: 8Kw

Anti-full Control: with pressure switch placed on the exit chute

防过满控制: 位于输出槽,配置压力开关

Material Feeding: manual or with automatic feeding units

原料喂入: 人工或配置自动喂入单元

Impurity or Patch Discard: with adjustable interceptor and recuperating vacuum system

杂质去除: 配置有可调的拦截器和真空系统

Accessibility: with hinged covers safety interlocked

辅助装置: 安全连锁的铰链防护罩

Productivity: Productivity: Highly productive with best possible quality levels

产量: 高质高产

For Recycling:

适用范围:

- Waste sweaters, fabrics, yarns, rovings and slubbing of cashmere, wool, cotton, acrylic

羊绒、羊毛、棉、腈纶等的毛衫、布、纱线、粗纱条

- Non woven products

无纺布产品