Almer Tekstil is a relatively young company, with its spinning plant at Kayseri, Central Anatolia, established in 2002 to produce yarns for weaving and knitting. In 2005, Almer added compact spinning to its portfolio. With 24,000 spindles of conventional ring spinning and 28,320 for compact yarns, the plant is now a major producer of yarns in the count range Ne 20-100, including carded, combed, compact and elastane core options. Production capacity is 23-25 tons per day, some 50% of which is compact-spun. Around 50% of total output is exported.

Almer Tekstil位于安纳托利亚中部的开赛里,是一家相对年轻的公司,始建于2002年,当时主要生产针织及机织纱。2005年,Almer增加了紧密纺的业务。目前拥有传统环锭纺纱锭24,000锭,紧密纺纱锭28,320锭,这家工厂如今是Ne 20-100纱线的主要生产商,产品包括粗梳、精梳、紧密纺以及氨纶包芯纱等。产能为23-25吨/天,其中50%为紧密纺纱线,总产量的50%用于出口。

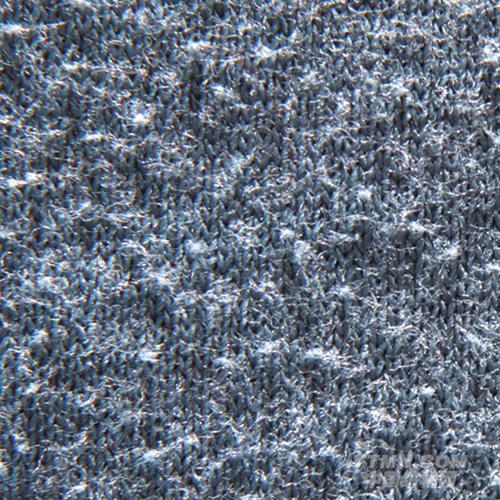

Hairiness – visible impact on fabric appearence

毛羽 -- 对织物外观造成明显影响

图二_由于高毛羽导致的起毛起球

As an USTER customer, Almer Tekstil has a strong awareness of the importance of consistent quality in a competitive environment – and the potential risks of any shortfall. That is why the company reacted immediately to complaints about hairiness levels in some of its compact yarns. Rejected fabric samples were examined and showed problems on fabric surfaces, in both raw and finished material. Further investigations revealed that some other yarn producers had introduced routine tests on hairiness levels in yarn. Afterwards Almer Tekstil acknowledged that hairiness was a key quality parameter for compact yarn.

作为乌斯特的客户,在竞争激烈的市场环境中,Almer Tekstil对于保持稳定一致质量的重要性有着强烈的意识,同时也十分明白稳定一致质量的缺失可能带来的潜在风险。正因为如此,当部分紧密纺纱线由于毛羽问题产生投诉时,这家公司会迅速进行响应。通过对被投诉的织物样品进行检测,在坯布和成品布表面上都发现了问题。进一步调查显示,其他纱线生产商已经引进了纱线毛羽的常规检测。至此,Almer Tekstil意识到毛羽确实是紧密纺纱线的一项关键质量参数。

Tülay Fidan, Almer's head of quality control, explains how the company set about dealing with these quality concerns and addressing customer complaints: “My manager and I were able to convince the owner to invest in the USTER®ZWEIGLE HL400 hairiness length measurement instrument. We know that yarn hairiness impacts on many aspects of fabric quality for various textile end-uses, and the crucial benefit is that spinners can forecast how a yarn will look and perform downstream, based on the measured data from the USTER®ZWEIGLE HL400. This has enabled us to eliminate the hairiness problems, as well as increasing efficiency in productivity.”

Tülay Fidan,Almer的质量控制负责人,对于其公司是如何处理这些质量关注点以及客户投诉如是解释:“我和经理一起说服了工厂主对USTER® ZWEIGLE HL400毛羽仪进行投资。我们都知道毛羽会对不同终端用途的织物质量造成多方面的影响。此外,这项投资最重要的益处是纺厂能基于USTER® ZWEIGLE HL400 的测量数据预见纱线的外观及其在后道中的性能表现。这能帮助我们排除毛羽问题并增加产能、提高效率。”

S3 – key for compact yarn

S3 -- 紧密纺纱线的关键

<<上一页[1][2][3]下一页>>